Please wait.

Please wait.

Team project, Aug 2015 – May 2016

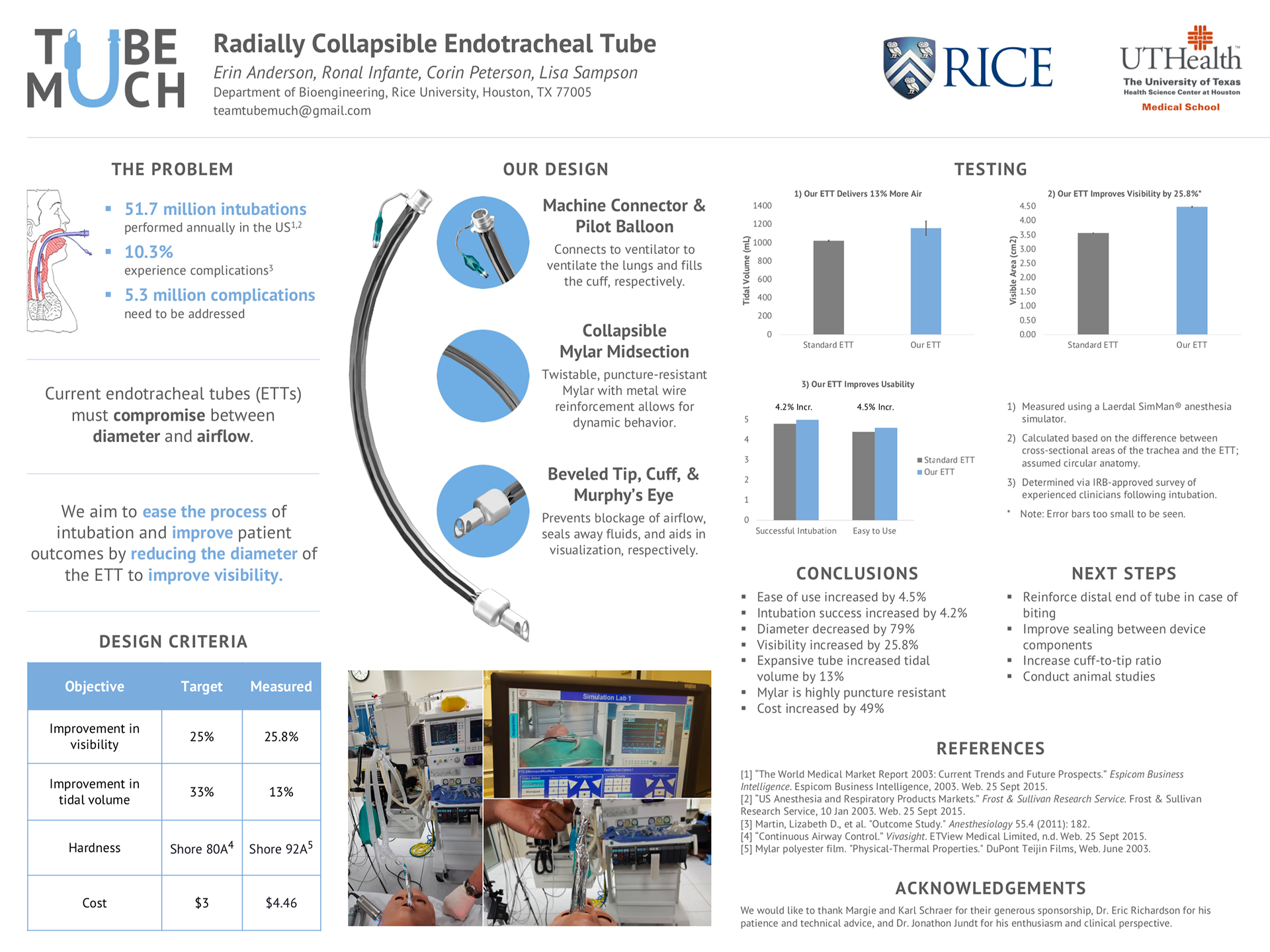

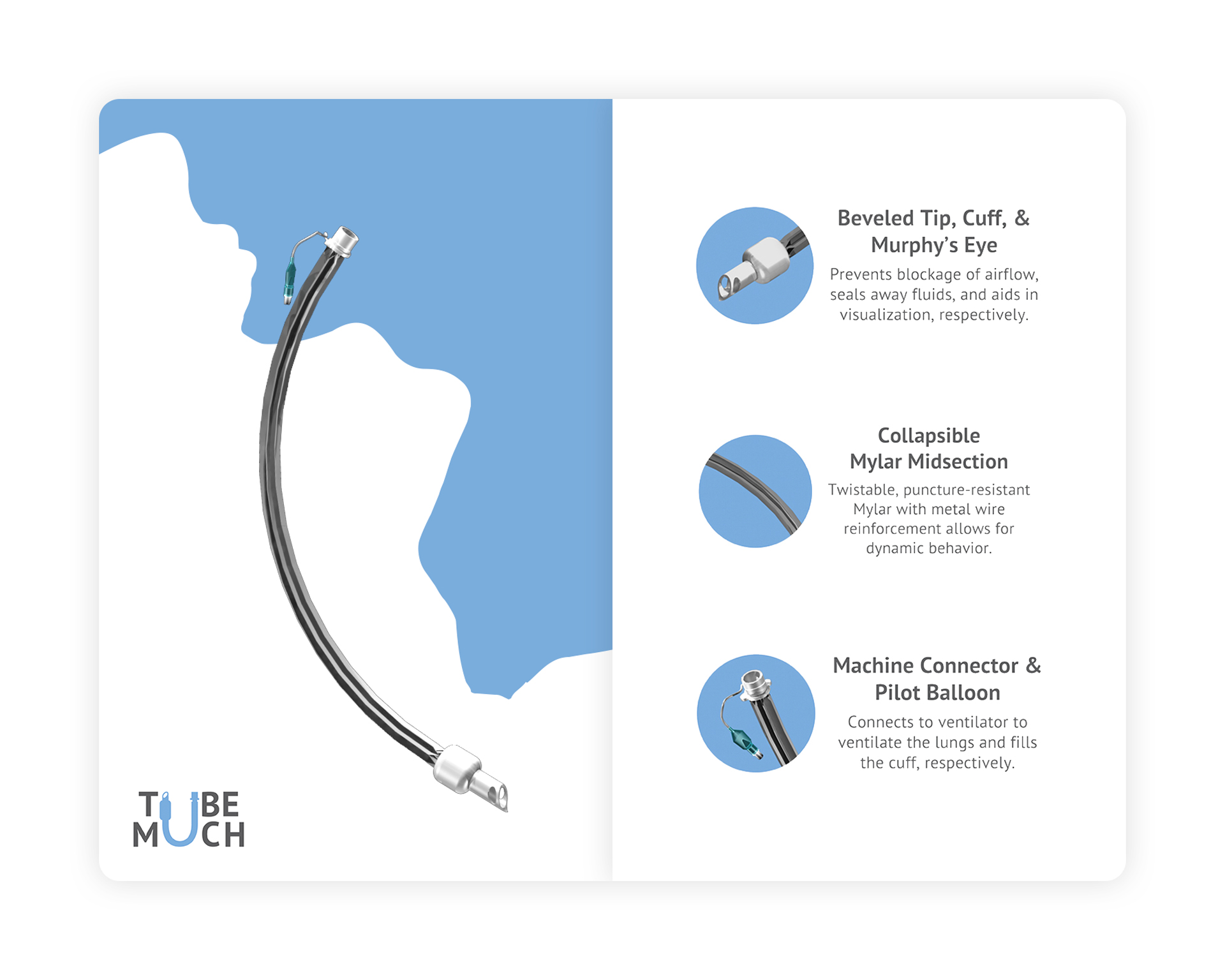

Developed a patent-pending, radially collapsible endotracheal tube that improves patient outcomes by helping EMTs and clinicians see around the device while securing the airway of a patient that cannot breathe.

Of the 51.7 million intubations that occur annually, 10% encounter complications. During intubation, endotracheal tubes (or ETTs) are inserted into a patient’s trachea. They are used to administer general anesthesia or ventilate the lungs during surgery, meaning that every person who undergoes a surgical procedure must be intubated.

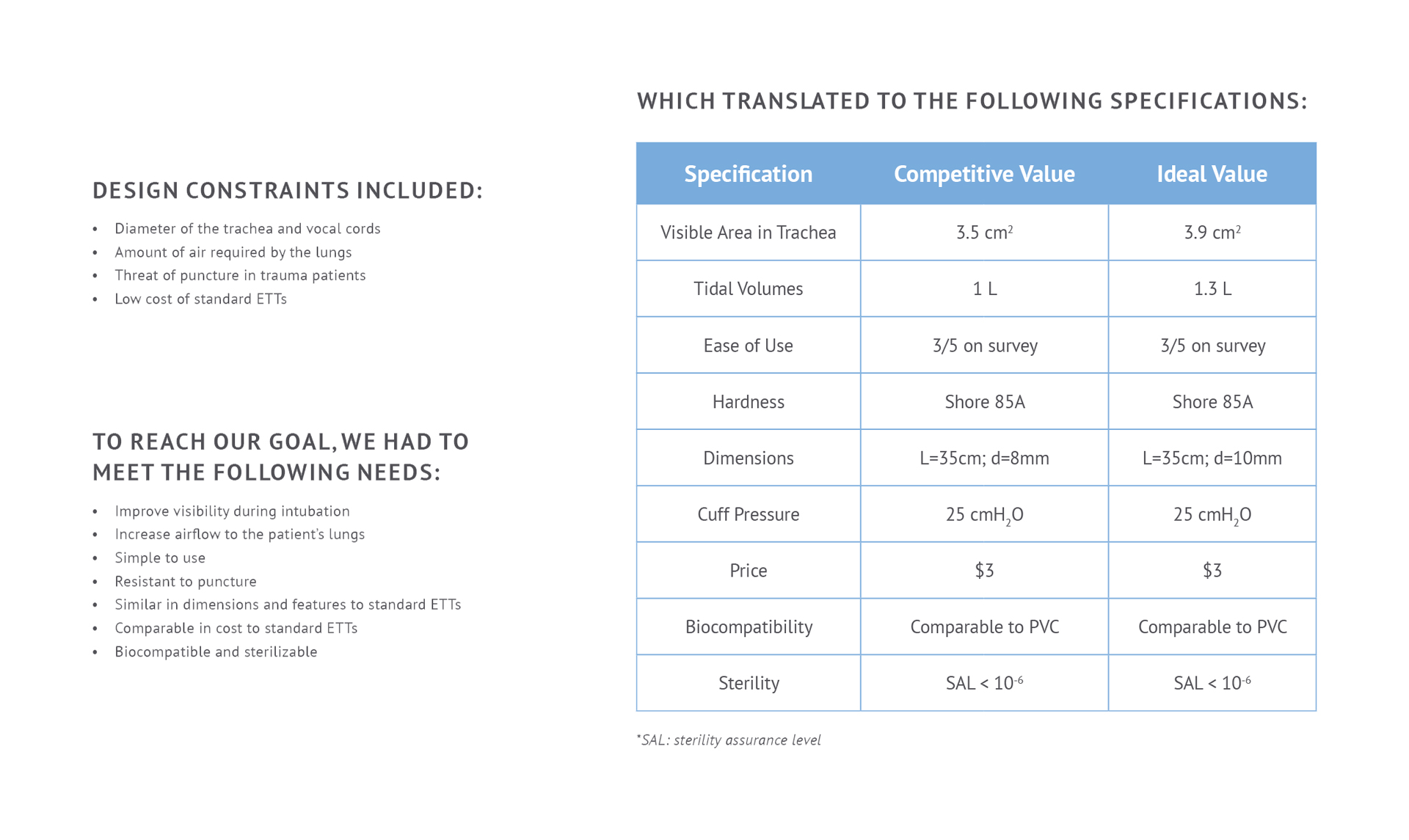

ETTs should have a diameter that is small enough to ease intubation, while large enough to maintain sufficient airflow to the lungs. However, current ETTs prioritize airflow (and thus have larger diameters), reducing visibility around the tube during intubation. As a result, clinicians may hit the surrounding tissue, causing injuries that can ultimately become major medical and financial burdens to the patient.

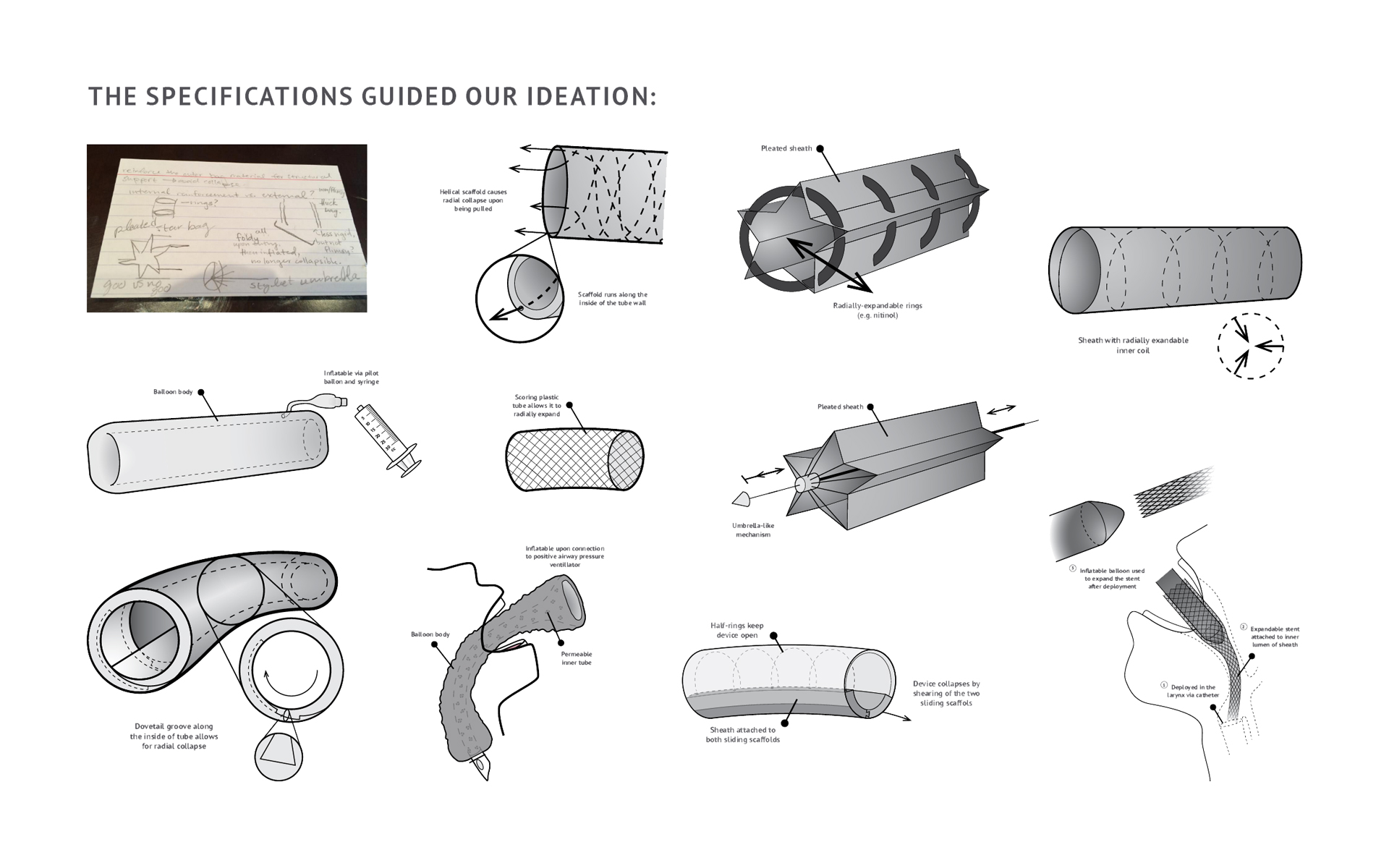

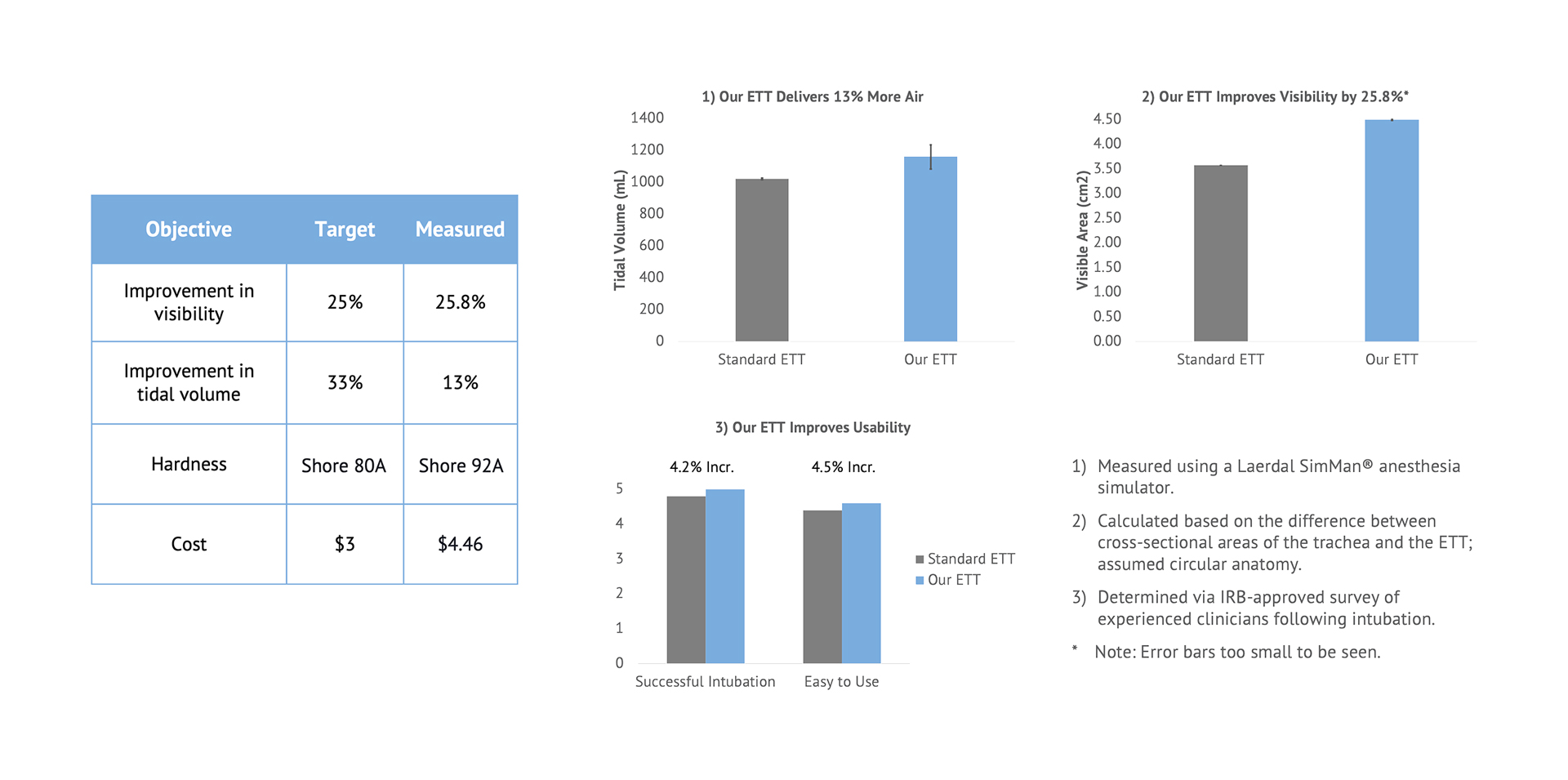

We designed a novel device that inserts at a diameter of 2 millimeters to ease intubation and then radially expands to a diameter of 10 millimeters to enhance airflow by 13% compared to current ETTs. Using this collapsible design, we have increased visibility by 26%, leading to easier and more successful intubations as noted by clinicians within our IRB-approved study.

Our team spent a year identifying needs and specifications, completing market analysis, FMEA, and LBM cost analysis, and developing a finalized prototype.

Our project was sponsored by Margie and Karl Schraer and Dr. Jonathon Jundt. The design work for this project was supported by the resources of the Oshman Engineering Design Kitchen and the UTHealth McGovern Medical School.

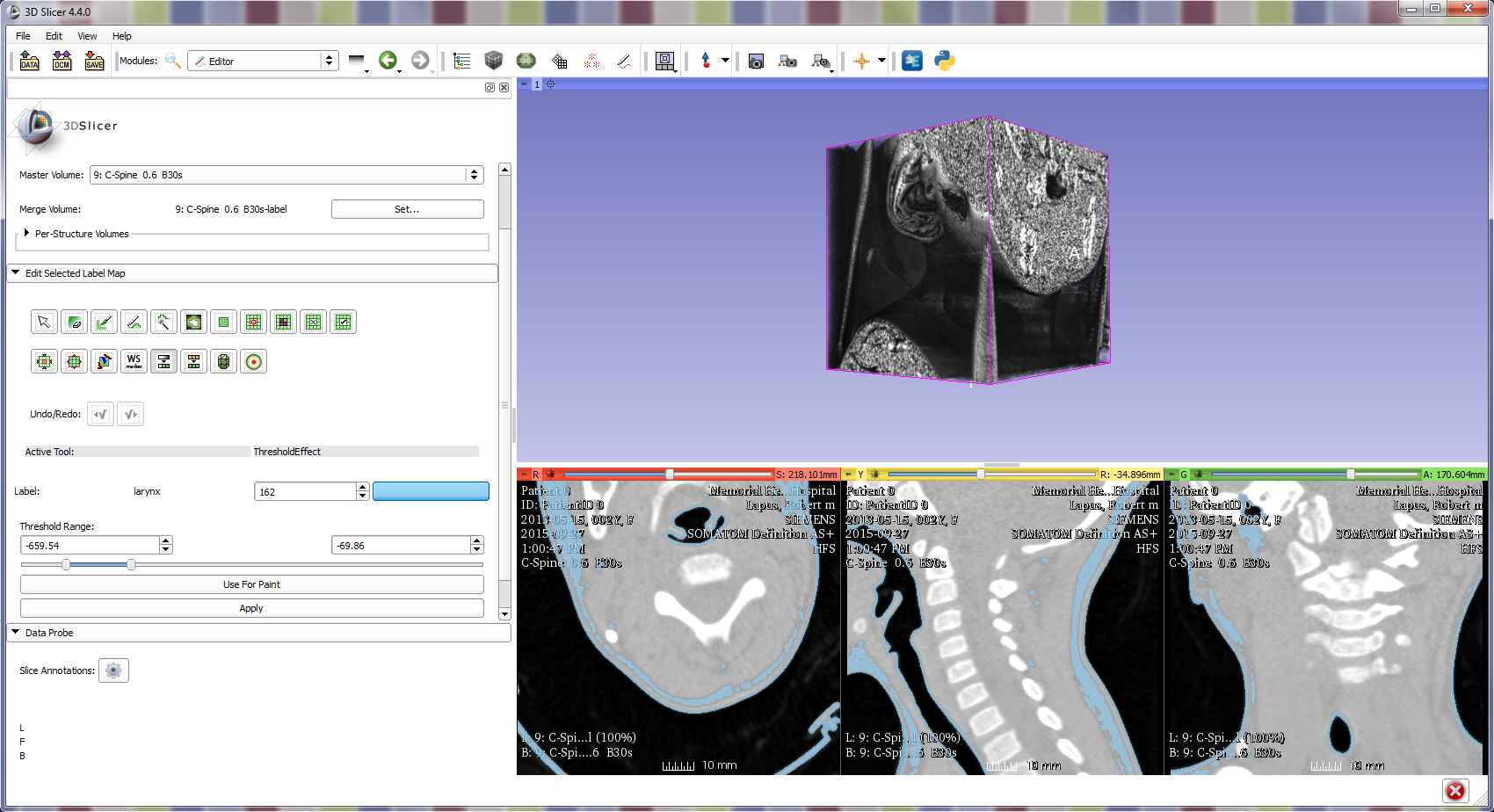

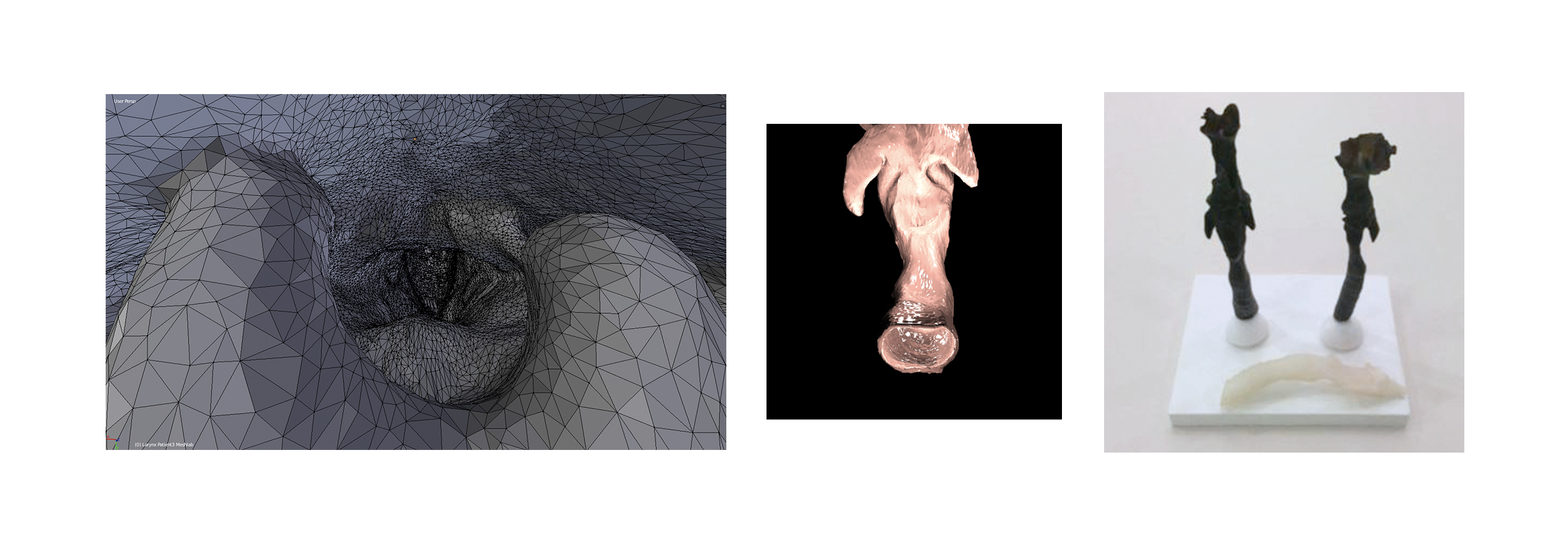

To help our team visualize the anatomy and scale of a human larynx, I developed male and female larynx anatomical models from de-identified clinical CT scans of the cervical spine region. These models are currently on display in the Oshman Engineering Design Kitchen trophy case.